Sustainable pigging technology: enhancing efficiency and lowering the cost of operation

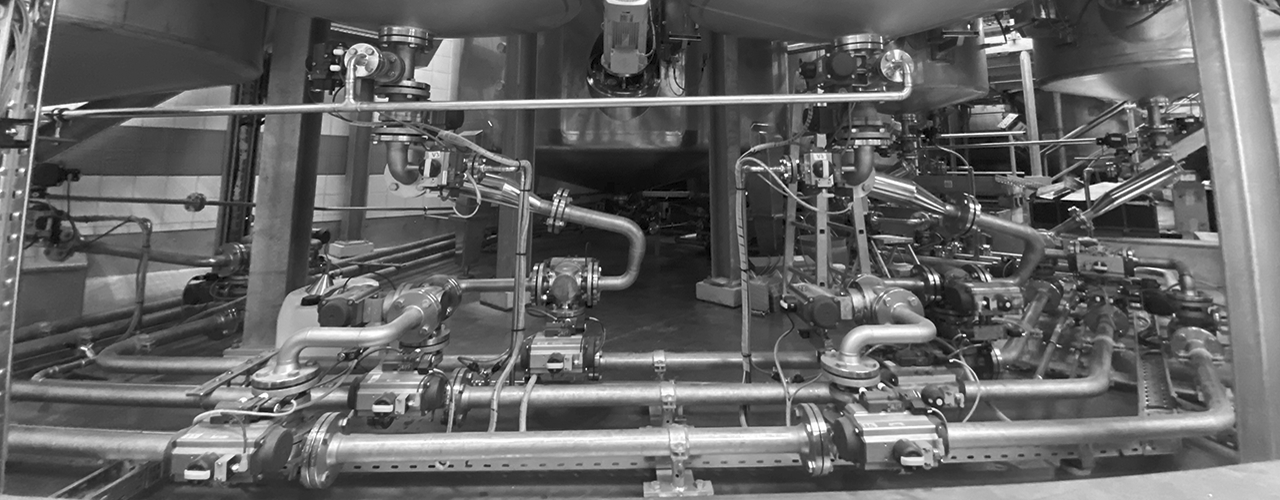

Our pigging systems help make product transfers and filling operations in process plants more cost effective. Benefit from turnkey pigging systems made in Germany for the best cleaning performance with full product recovery.

Our valves ensure the highest level of plant safety and help reduce the cost of service and maintenance. Our patented pigs ensure that the cleaning performance and product quality remain consistently high for multi-product transfers. Single-pig and twin-pig systems offer maximum flexibility in process distribution networks.

Thanks to our in-house hardware and software engineering, plant components with a long service life are designed to optimally interact with one another.

Our experienced engineering team supports you throughout all stages, from planning to assembly and start-up of the systems.

Find out more about our pigging systems

Turnkey pigging systems engineered by SAMSON PFEIFFER can recover almost all product residues from the pipeline. Our pigs ensure thorough cleaning of the pipeline and valves within the entire pigged system. For decades, we have been a leading supplier of this technology especially to the chemical industry.

Our pigging systems eliminate cross-contamination between products during cleaning processes. This makes draining and flushing operations less complex while boosting plant productivity.

SAMSON PFEIFFER: Your Specialist for Pigging Systems

Less space and better product quality

Our pigging systems guarantee that multiple products can be conveyed in the same pipeline without the risk of cross-contamination. This makes the need for dedicated pipelines for each product redundant and reduces the space required. Cross-contamination between products is effectively eliminated. As a result, product purity and quality requirements can be met.

Combining efficiency and high product purity

Our pigging systems guarantee an exceptionally thorough cleaning performance. Our patented pigs and precise valve technology help achieve maximum product quality, minimize product loss and optimize cleaning operations. Our pigging solutions combine efficiency and high product purity.

Additional control and flexibility

Single-pig systems are the ideal solution for product transfer operations especially in tank farms and onshore installations. Twin-pig systems ensure precise, bubble-free filling and prevent product foaming. It is even possible to reverse the product flow in twin-pig systems as an additional control feature.

Interesting facts

The pig is at the heart of every pigging installation. The cylindrical, ideally flexible pig is propelled pneumatically and/or hydraulically through the pipeline for cleaning. The pig is specially designed to exactly fit a given process plant. It perfectly matches the valves and pipeline of the process plant to achieve the best cleaning performance.

The high degree of automation makes our pigging systems highly efficient and more economically over the entire life cycle than conventional cleaning methods.

Contact us to find out more about our pigging systems tailor made for your specific needs.

- Turnkey Pigging Solutions Pigging to Reduce Load on Production Plants And Increase Productivity