SAMSON PFEIFFER

Valves from SAMSON PFEIFFER stand for maximum precision and technical excellence.

Reliable, powerful and sophisticated - we offer optimum solutions for your demanding applications.

From our production site in Kempen, Germany, we supply our customers with a wide range of industrial valves – particularly valves with PTFE and PFA linings – as well as state-of-the-art pigging systems.

Valves by SAMSON PFEIFFER are characterized by safe, reliable and fault-free operation, even under extreme conditions and in complex applications.

Our customers know that they can always rely on the PFEIFFER team, particularly when it comes to special requirements. Get in touch with us and we will find a tailor-made solution to fit your specific needs.

We love what we do. Our staff and customers feel and appreciate that. Inspiration, motivation, professionalism, environmental and social consciousness are deeply engrained in our DNA.

Find out for yourself and get to know us!

Our Solutions

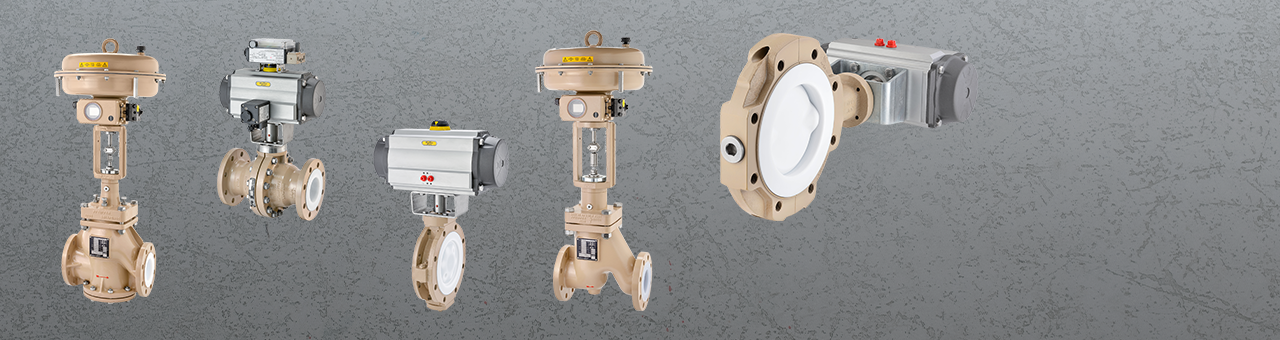

Media flow through our globe valves in the flow-to-open direction. The position of the valve plug determines the cross-sectional area released between the seat and plug. A PTFE bellows seals the valve body against the plug stem. Inside the valve body, the medium flow is deflected, which results in a higher flow resistance. As a benefit, globe valves have a smoother control response.

Globe valves by PFEIFFER combine the excellent mechanical properties of metal bodies with the corrosion resistance of fluorocarbons, which we use for our PFA and PTFE linings.

Special solutions, e.g. reinforced PTFE bellows seals or adjustable packings, can be implemented without any problems thanks to our wide product range. Bellows seals made of special metals, such as titanium or Hastelloy®, are available from our well-structured modular valve portfolio as well.

Butterfly valves are suitable for both directions of flow. The flow rate is determined by the area released between the butterfly disk and seat ring. A quarter turn of the disk can release or shut off the medium flow.

Depending on their application, butterfly valves can be lined with PFA or PTFE. Our valve bodies are available made of steel, stainless steel or special alloys.

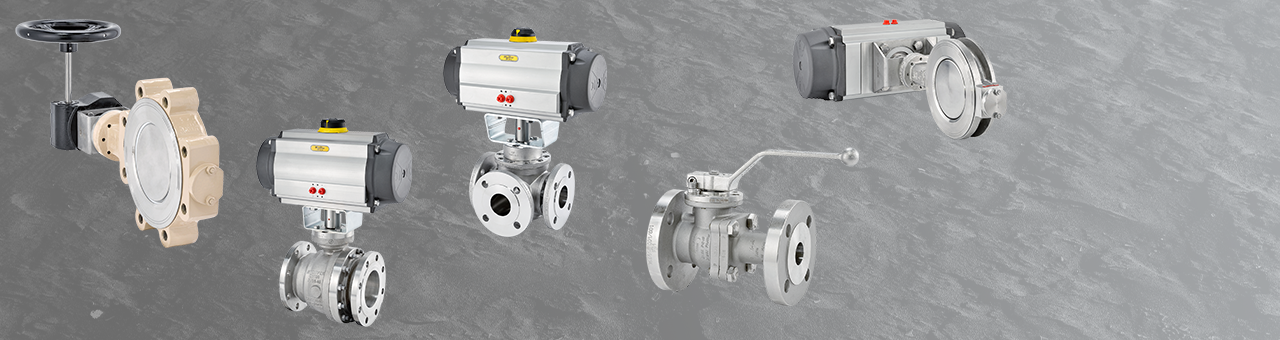

Ball valves are suitable for both directions of flow and offer an unobstructed, straight-through flow path. The ball with its cylindrical passage rotates around a shaft. The opening angle of the ball determines the flow rate across the free released area between the body and ball channel. A quarter turn of the ball can release or shut off the medium flow.

Depending on their application, ball valves can be lined with PFA or PTFE. Our valve bodies are available made of steel, stainless steel or special alloys.

Our pneumatic rotary actuators are used to actuate rotary valves in process and plant engineering applications, such as butterfly and ball valves as well as other valve types with rotary closure members. When combined with a positioner, they can also be used for throttling service.

PFEIFFER Rotary Actuators (2010 Edition)

The single-acting or double-acting piston actuators are mainly used to meet the strict requirements that apply in chemical plants.

Pneumatic Rotary Actuators

The pneumatic rotary actuators come with a rolling diaphragm and central return spring. They are perfectly suitable for throttling service.

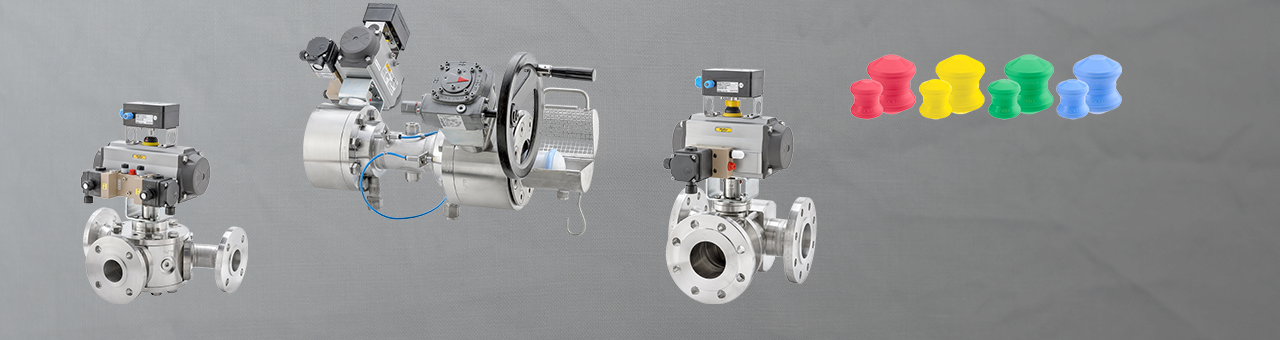

Sampling systems are used to take liquid samples from media flows without requiring a pipeline bypass.

Continuous Sampling Systems

Continuous sampling systems take samples with varying volumes from a flowing medium. As there is a direct connection to the environment, we recommend to fit continuous sampling systems with a dead man's handle.

Discontinuous Sampling Systems

Discontinuous sampling systems take samples with a defined volume from a flowing medium. As a result, pressureless sampling and consequently withdrawals at high pressures and from vacuums become possible for liquid media. There is no direct connection to the environment.

As the sampled volume per cycle is defined, improper operation due to excessive opening times is ruled out, which also prevents any risk of spillovers.

Pigging is a modern way of moving gases and fluids through pipelines in the chemical industry. This technology is used in all applications where an efficient transport of materials must be ensured. Benefits of pigging systems include that small batches of different substances can be transported through pipelines, that only minimal amounts of solvents are required for cleaning, and that instrumentation and control systems can be implemented to automate pigging operations. Our pigging systems are environmentally conscious solutions with low cost of investment and operation.

PFEIFFER provides state-of-the-art pigging solutions. We use the expertise and experience acquired in cooperation with competent partners to plan and implement piggable pipeline systems for industrial processes.

Constant monitoring and inspections allow us to comply with the applicable quality standards. As a supplier of turnkey pigging solutions, our job is not done when the system has been started up. We also take on the maintenance of the system when it is up and running.

The demands placed on the dimensional accuracy and surface texture of the inside surfaces in piggable pipelines are very high. We can fulfil these demands by using smaller tolerances than those stipulated in the DIN standards, by applying an optimized bending method for pipe elbows and by orbital welding with a patented purging method.

» Find piggable valves » General information about pigging systems